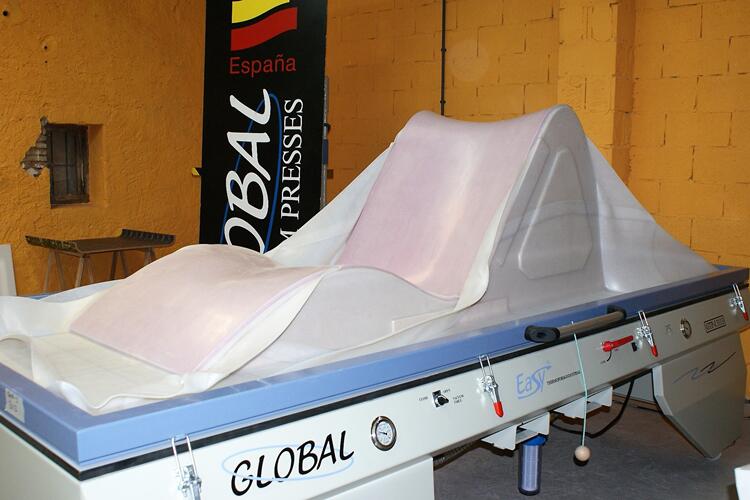

Vacuum Membrane is a premium-grade, transparent silicon rubber sheet designed for use in vacuum presses. With exceptional elasticity and a working temperature of up to 250°C, this lamination diaphragm provides a heat-resistant and flexible surface for shaping and molding materials with precision and durability.

But, where can you import silicone vacuum membranes?

The best answer is China.

China remains as the world’s largest manufacturing base of rubber and plastic sheets. Silicone vacuum sheets are just one of the branches of these products. Those people who have been focusing on woodworking and thermoforming industries are more likely to import vacuum forming sheets from China.

It seems very easy for a veteran buyer to find what he wants.

Nevertheless, for newcomers, the process of sourcing can be challenging. It often proves to be a time-consuming, laborious, and unpleasant experience.

Importing vacuum presses membranes from China can be a cost-effective way to source high-quality products for your business. However, the process can be complex and there are potential pitfalls to avoid.

Good products aren’t always easy to find. That’s where we come in to assist you.

In this article, we’re going to explore the fundamental aspects of finding the right supplier for your upcoming project. We will provide suggestions on how to search for potential suppliers and discuss effective strategies for engaging with them. Additionally, we will highlight key steps when collaborating with suppliers to import thermoforming materials for your applications.

Now, here we go!

How Do You Find Suppliers?

Whether you’re making custom wood doors or 3D laminated products in a vacuum membrane press, finding the right supplier for your applications is crucial to your success.

Suppliers control your product’s cost, quality, packaging and shipping. Here are 5 ways you may consider as below:

Current vendors

Placing silicone membranes directly with existing suppliers is the fastest and most efficient way.

This is primarily due to the mutual familiarity and in-depth understanding between both parties, which accelerates the completion of orders through streamlined communication, enhanced product quality, and optimized pricing. The past good cooperation experience and shared knowledge between the buyer and supplier contribute to a faster order fulfilment process.

One point to note is DON’T give more than 55% of all orders amount to the same supplier. Due to constraints in space, we will not delve into detailed explanations here.

Recommendations

Ask acquaintances and other people in your line of business if there are any suppliers that they’d recommend. This can be a good way of getting an honest evaluation of a reliable supplier – unless that is, you talk to a competitor who feeds you with misinformation.

In most cases, the cost associated with trial and error is relatively low.

Nonetheless, there are potential risks involved if your friend has not personally had any dealings with this recommended supplier.

Trade shows and exhibitions

Trade shows and exhibitions offer face-to-face opportunities to discover and identify suppliers. It can be a good idea to talk about business details on the spot with potential suppliers. Being open to networking is important as you might meet other visitors who can offer valuable advice.

Attending these trade shows provides a more comprehensive understanding of the available options and a better sense of the industry landscape compared to solely relying on directory searches.

Notes:

Suppliers at the exhibitions like to grab orders at low prices and then raise prices later. It is important to be able to distinguish and avoid certain exaggerations and disguises as well.

Online searches

Local search engines (like Google.com), B2B marketplaces and social media have made it much easier to reach out to overseas sellers, so make good use of these online tools.

In recent years, you have developed a dependence on the convenience of searching on Google and finding desired information within the top few search results.

However, some excellent suppliers may be less focused on online marketing. Typically, their websites appear outdated, lack sufficient information, and exhibit poor search engine optimization.

Here we suggest you need to explore page two of Google search results and beyond. You can also try to use a variety of long-tail keywords. For example, words like “silicone sheets for vacuum press”, “vacuum pressing silicone membranes”, and “silicone membranes for making thermofoil doors” may be used interchangeably, so you should search for all of them.

It may help to make yourself familiar with online buying process and improve the quality of your searches, thus, your results.

Remarks:

During your search journey, it is always uncertain who they are, how their company operates, the quality of their products, and whether they are reliable.

This requires further contact and communication following with the article’s contents as follows.

Key Factors To Consider Before Choose A Supplier

You need a supplier with a highly matching degree. Probably, maybe he or she is not perfect.

Here are key factors to consider when selecting suppliers.

Communication

A competent supplier can demonstrate the quality of their products from various perspectives through effective communication. As a seasoned buyer, “How much will this cost?” won’t be the only concern.

Both parties communicate well and understand each other’s needs, which can make your project move forward quickly.

Quality

While your supplier may offer an incredibly low price, it is crucial to ensure the quality meets your standards. Obtaining silicone membranes at a discounted rate is of no use if they are much easier to be torn and worn.

To evaluate the supplier’s work or products, explore options such as requesting samples or customer endorsements. When applicable, consider visiting their premises to personally witness their quality control measures.

Price

After identifying several manufacturers of interest, it is advisable to obtain quotations. It is recommended to gather a minimum of three quotes to facilitate a comprehensive comparison of available options.

Price is a pain point in choosing the right supplier, but it’s not the only one.

Delivery time

What is the estimated time from the issuance of the order to the actual delivery? You do not want to work with a supplier who takes three months to deliver a membrane sheet. It’s better to avoid keeping customers waiting for months to receive their orders when a product goes out of stock.

Payment

Will the supplier offer credit terms, and if so, what is the credit limit? How many days will be allowed to pay the invoice? If you pay promptly, would you get a discount? If the first order is paid in advance, would the supplier consider extending credit for future orders?

Others

In addition to the key factors mentioned above, there are other important aspects to consider when selecting a supplier. These factors may vary depending on your specific requirements and industry, such as MOQ limit, Package details, Customer service, Financial stability, and so on.

To make an informed decision about whether to collaborate, it is crucial to carefully evaluate and compare providers across multiple dimensions. By considering various factors, you can assess the suitability and compatibility of potential partners.

It’s easier said than done. Probably, you can try to work with a supplier with the following steps.

A Business Workflow About Importing From China

Sending an inquiry

The most effective way to contact a supplier is through email. However, if you encounter delays in their response, it is advisable to follow up with a phone call.

A reputable supplier will strive to provide prompt responses to your messages, typically within a 24-hour timeframe or even earlier.

Negotiating with a supplier

Win-win strategies are good for both sides of the negotiation. You’ll have to communicate with suppliers on your own. There are three main ways to do this:

- Phone calls

Look for companies that are responsive and eager to work together. If someone is sluggish in responding to your emails and messages, it may raise doubts about their reliability and suitability for your business.

Engaging in negotiations with a supplier does not guarantee obtaining vacuum silicone sheets at a low price. Instead, it aims to secure the products at the most favorable price.

Evaluating the supplier’s input costs, such as labor and material expenses, as well as mark-ups, will assist in determining the reasonableness of their pricing.

At this stage, be sure to negotiate a payment method with the supplier. The main incoterms are EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAT, DAP, DDP, etc.

Testing samples

A sample request shows you’re highly interested in silicone membranes and motivated enough to invest a small amount to prove it.

During the sampling process, you’ll also be able to assess what it’s like to work with that particular seller. Is communication prompt and seamless? Did the seller offer the level of assistance you require? This is your test run.

Placing an order

After successful negotiations and samples evaluation, it is time to place orders from this supplier.

Here you have to explain clearly the sizes, quantity, packaging details, payment and shipping terms.

Making a deposit

After issuing an official order, the next step is payment. Typically, a 30% deposit of the total amount is required before the supplier starts mass production working on your order.

Inspecting the products

Conducting thorough product inspections to ensure they meet the required standards is of utmost importance, and significant focus should be placed on this step.

If you are unable to physically attend the inspection, you can request the manufacturers to provide you with pictures and videos of the products to verify their condition.

A reputable supplier should have compensation measures in place in case a customer identifies any faults in the delivered products.

So before the shipment, Packaging is also a concern to avoid damage in transit.

Paying the balance

Once all preparations are complete, you will need to make the final payment, which is the rest 70% of the total amount.

In certain cases, after successful negotiations, you may opt to make a 50% payment before the shipment, followed by a 20% payment after delivery.

The specific payment method depends mainly on the results of the negotiation with the supplier in the early stage

Shipping the cargoes

A shipping method refers to the means by which you transport vacuum membranes from China to your country. Common shipping ways include:

By air

Air freight such as DHL, FedEx, UPS, TNT, and certain express special lines typically provide home delivery services. However, it’s important to note that local customs taxes and fees are not included in their service.

In general, shipment by air is the most costly method. However, there are situations where it is justified due to the faster delivery and better condition of the silicone sheets you’ll get.

By sea

When dealing with large and bulky products that don’t require immediate delivery, it is highly recommended to opt for ocean shipment as the preferred method.

Shipping goods by sea proves to be more cost-effective in such cases, allowing for significant savings in transportation expenses. The slower transit time associated with sea freight is often outweighed by the economic advantages it offers. By utilizing ocean shipment, businesses can efficiently transport their bulkier products while optimizing their logistics and reducing overall shipping costs.

By train

Rail transportation is only available for shipping goods between China and Europe or Southeast Asia. With the establishment of the Belt and Road initiative, there has been a significant improvement in connectivity between China, Central Asia, and Europe.

The time limit ranges from 15-35 days. The best aspect is shipping and customs duties are included. You just sit at home and wait for the discharge of your cargo.

In summary, no matter whether you have a shipping agent in China or we take the shipment, the choice of the most suitable shipment method depends on various factors including the urgency of delivery, product volume, budget limitations, and specific requirements.

Doing customs clearance

When the goods arrive at your local seaport or at some warehouses, you gotta do customs clearance by your side or with the help of a broker. This usually means you have to pay some duties to be able to get the products.

The time required for customs clearance depends mainly on the efficiency of your local customs office and your own capacity to clear customs.

Receiving the goods

After receiving the products, the first time to detect whether the goods and packaging are damaged. If there is damage, you need to promptly give feedback on these issues to the supplier. A good supplier also provides excellent after-sales service.

Additions: Things You Should Know About Importing

Incoterms (Trade Terms)

What are Incoterms?

Incoterms are a set of internationally recognized rules which define the responsibilities of sellers and buyers in the export transaction.

The primary role is to make both the exporter and importer understand their responsibilities and tasks, costs, and risks from when a product leaves an exporting country to the importing country.

Incoterms clearly define the guidelines governing:

- Delivery points.

- Transportation costs.

- Export and import costs.

- Insurance costs.

The seven Incoterms® 2020 rules for any mode(s) of transport are:

EXW – Ex Works (insert place of delivery)

FCA – Free Carrier (Insert named place of delivery)

CPT – Carriage Paid to (insert place of destination)

CIP – Carriage and Insurance Paid To (insert place of destination)

DAP – Delivered at Place (insert named place of destination)

DPU – Delivered at Place Unloaded (insert of place of destination)

DDP – Delivered Duty Paid (Insert place of destination).

Note: the DPU Incoterms replaces the old DAT, with additional requirements for the seller to unload the goods from the arriving means of transport.

The four Incoterms® 2020 rules for Sea and Inland Waterway Transport are:

FAS – Free Alongside Ship (insert name of port of loading)

FOB – Free on Board (insert named port of loading)

CFR – Cost and Freight (insert named port of destination)

CIF – Cost Insurance and Freight (insert named port of destination)

To help you further distinguish between responsibilities and obligations, please refer to the following image.

Who is importing these silicon vacuum membranes?

Vacuum membrane is not a popular product in the traditional sense. There are the top 3 major purchasing groups.

End users

Those customers who have a workshop or a factory focus on laminating PVC foil, wood veneer doors, production of furniture panels, and thermoforming of solid surface and thermoplastic materials.

Vacuum presses manufacturers and suppliers

The users mentioned above are required to operate their machinery in order to manufacture their products. Therefore, suppliers who offer vacuum presses typically provide their customers with one or two sheets.

Local wholesalers and retailers

These intermediaries sell silicone sheets and procure various types of rubber and plastic products from China, which they subsequently distribute to their local clients.

Conclusion

Importing silicone vacuum membranes from China can be a lucrative, exciting and, at times, challenging endeavor. It’s important that you understand the necessary steps in order to not only ensure your business is successful, but also sustainable, provided that you follow the right procedures.

Working with a reliable supplier from China (like China Deer Hunter) can help ensure that you get all the products quickly and safely to make importing from China seamless and easy.

Give us a call at (+86)13823789007 or email sales@cndeerhunter.com and you’ll instantly be in touch with a specialist who can get you the information you need right now.