In the current clothing production field, balancing cost savings and competitiveness is essential. Each purchase requires careful evaluation to optimize expenses and remain competitive. And yet it’s equally important to prioritize product quality and appearance, as customers expect flawless garments. Any visible faults can lead to demands for price reductions.

Achieving high-quality clothing production requires careful attention to the ironing process. To ensure the desired results, it’s important to overlay ironing tables and presses with top-quality foam paddings and coverings. These ironing covers play a crucial role in achieving the perfect finish for clothing items that meet international standards.

However

Lately, some customers have found themselves at a loss when it comes to how to cover their industrial ironing tables and presses.

The abundance of options for foam pads, fabrics, and felts has left them feeling overwhelmed and uncertain about which ones to adapt to their machine.

Navigating through conflicting and unprofessional advice only adds to their confusion, leaving them unsure of how to proceed.

Fortunately, you’ve come to the right place at the very right moment. In this blog post, I’m going to share with you 9 practical solutions to effectively cover your ironing tables and presses.

Let’s kick off today’s article with an informative video that will set the stage for our discussion.

General Information

The durability of a covering relies on factors like pressure resistance, hydrolysis resistance, and most importantly, heat resistance of the materials used. While long-lasting coverings may be more expensive, they provide consistent ironing results and minimize machine breakdowns by extending the replacement interval.

When choosing the ironing pads and covers, the first thing to consider is the heat resistance of each layer. If the heat resistance is the same, it is recommended to replace all layers at once at the end of their lifetime.

Alternatively, you can opt for coverings with increasing heat resistance, starting from the top cover down to the base layer that is in direct contact with the hot machine. In this case, replace the top cover more frequently, especially when it becomes dirty, and use the opportunity to inspect the functionality and permeability of the layers below.

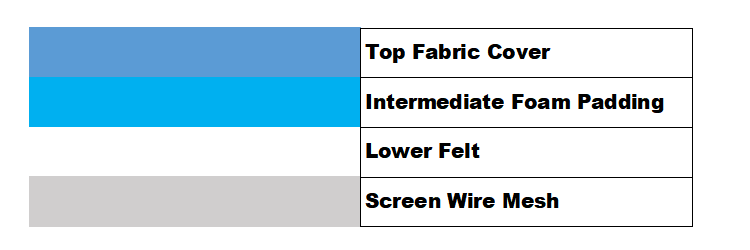

Basic Configuration For Ironing Tables And Presses

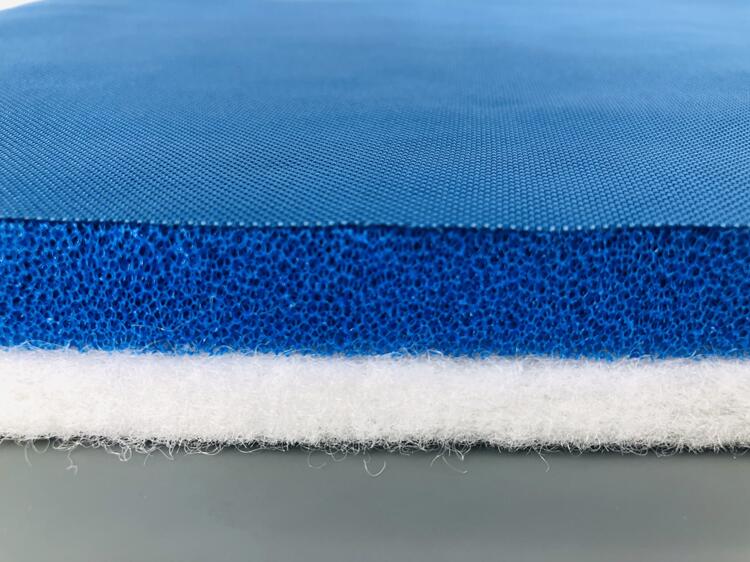

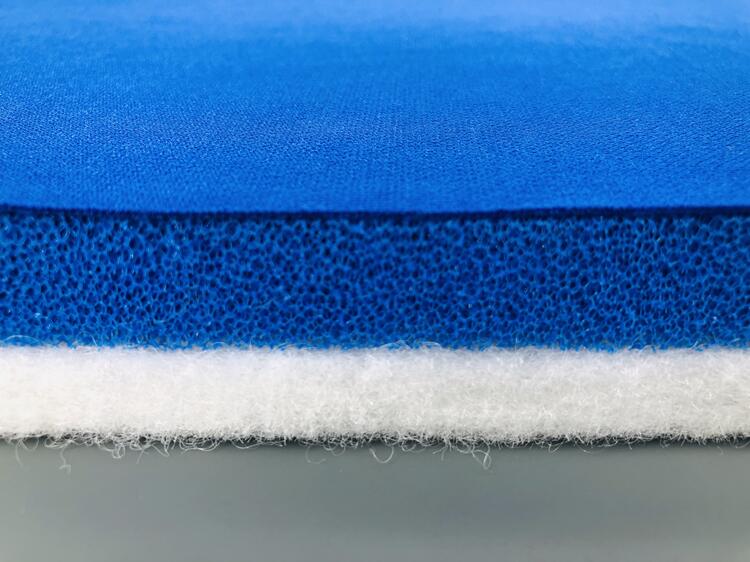

To get good steam distribution and heat resistance on your clothing presses and ironing tables, different machines may have different configuration options. But it’s really all pretty much the same.

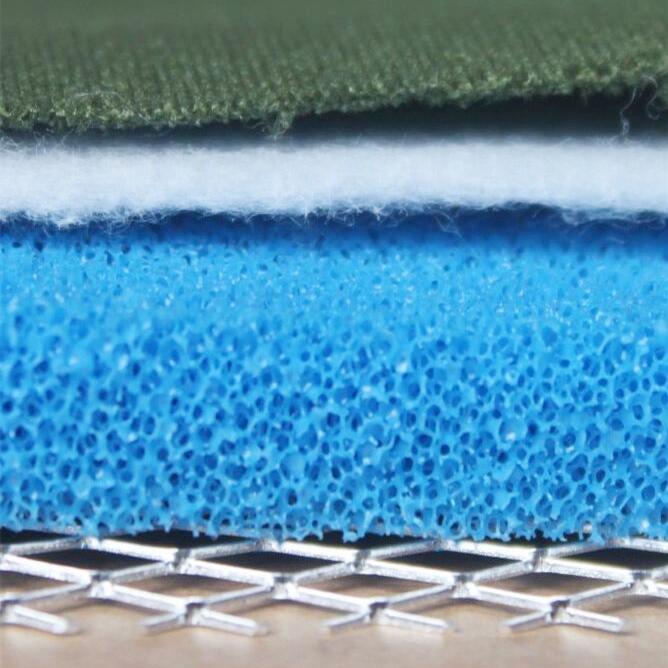

To ensure the best possible ironing outcome, each layer of an ironing table covering has a specific function. No layer is superfluous, and each part plays an essential role in attaining the desired result.

All layers together are responsible for the equal distribution of the steam which should come out of the covering evenly.

Most of your machines are usually equipped with our four-layer structure.

The covering starts at the metal surface of the ironing table:

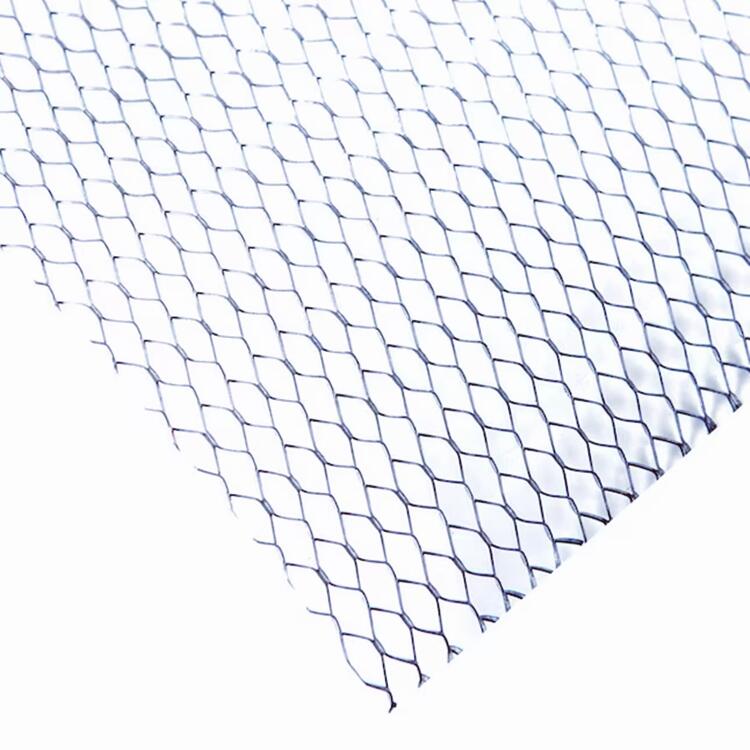

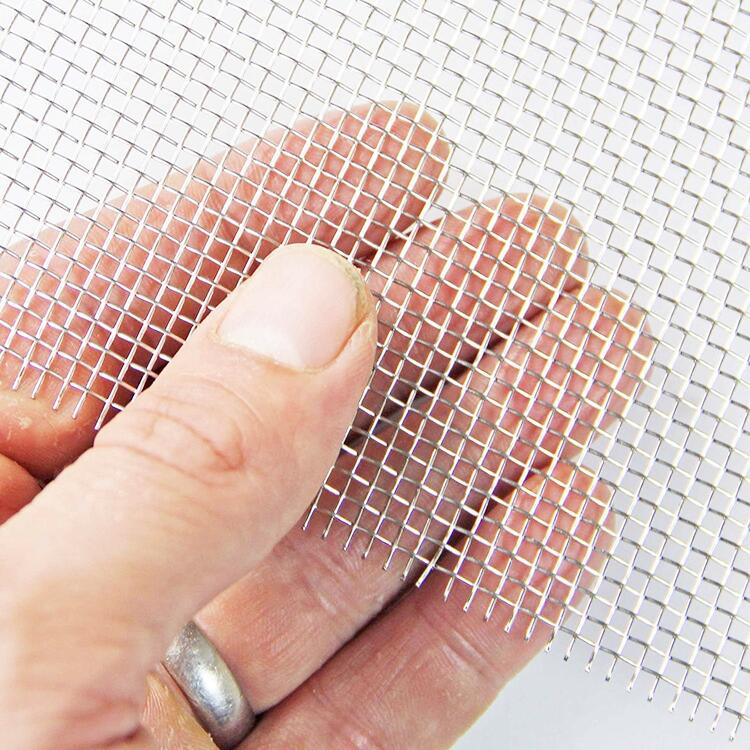

Screen wire mesh

The purpose of this mesh is twofold: to ensure a steady and uninterrupted flow of suction and blown air, and to serve as a safeguard against moisture that could potentially damage the upper layers.

Regular wire mesh sheets are Copper Mesh, Stainless Steel Mesh, Aluminum Mesh and Galvanized Iron Mesh.

|  |

| Aluminum Mesh Sheet | Steel Zinc-plated Net |

Kindly Reminder:

Actually, in most cases, this layer is not even used. This is mainly to reduce the cost.

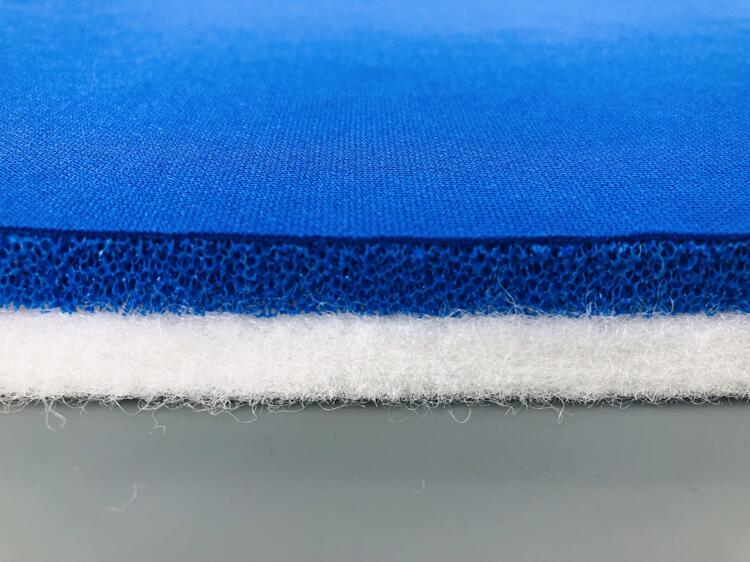

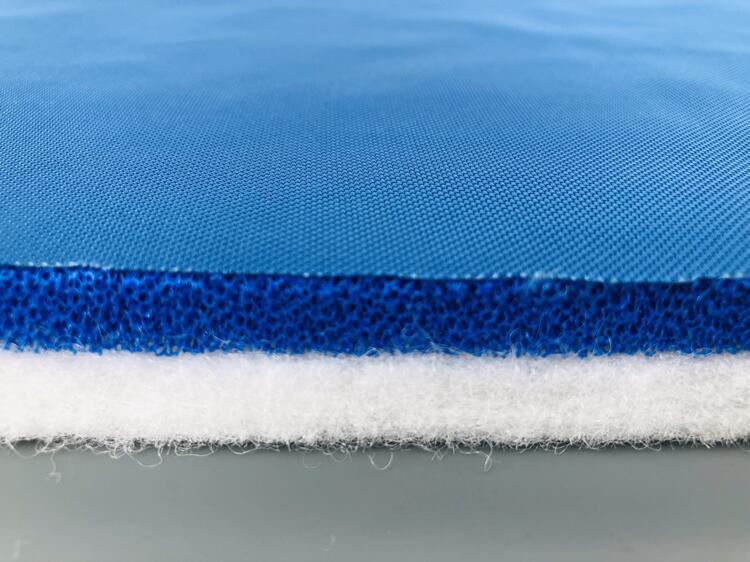

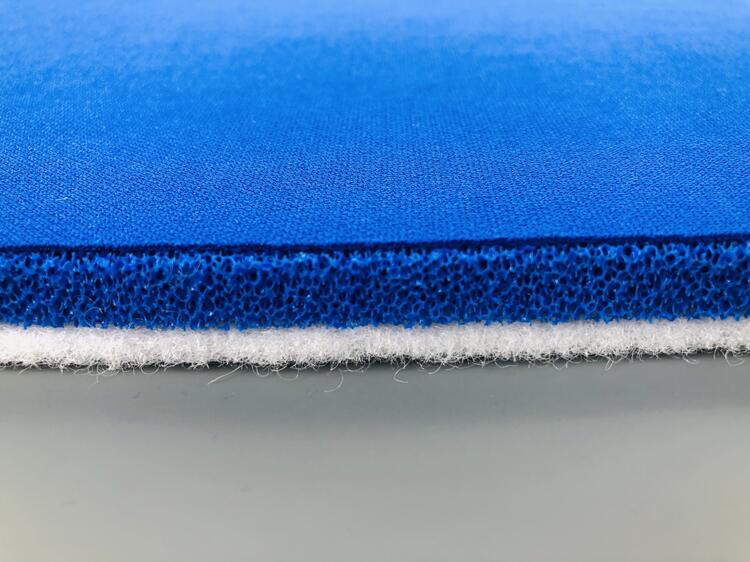

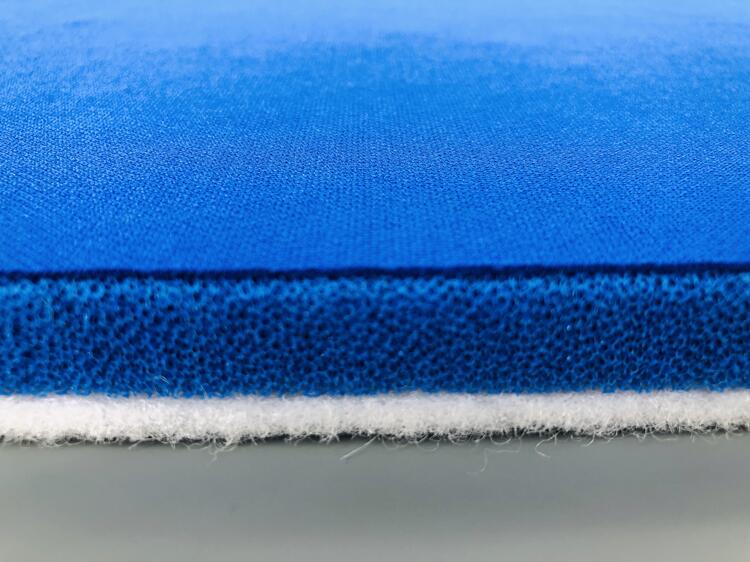

The lower padding

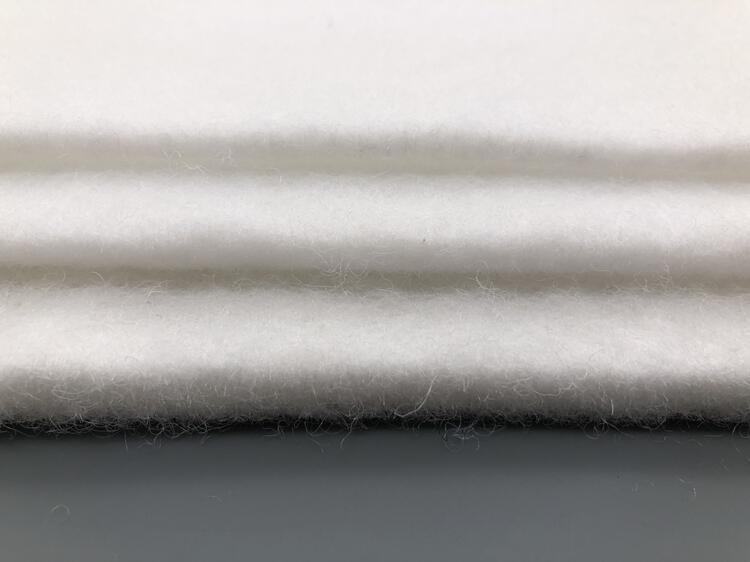

This layer acts as a protective barrier, shielding the upper paddings and clothing from excessive heat. A soft polyester needle felt is frequently chosen because of its economic suitability. Generally felts are used to spread the steam equally and to protect the clothing from spots caused by uneven steam distribution.

Regular felts are: P-300, P-600 and P-802.

However, sometimes a silicone perforated foam pad is used as the lower padding.

Notes:

Here, we do NOT recommend bonded foam (made from industrial leftover materials). Although the price is very low, it is not safe or stable. The replacement frequency is too fast.

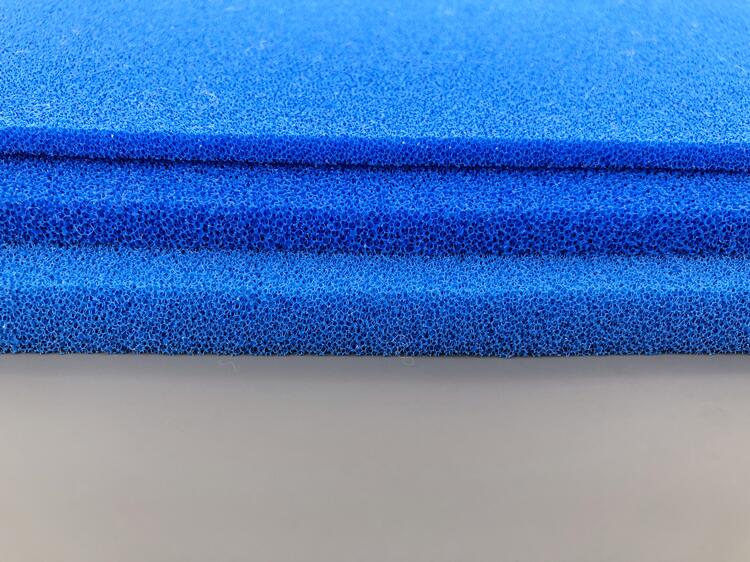

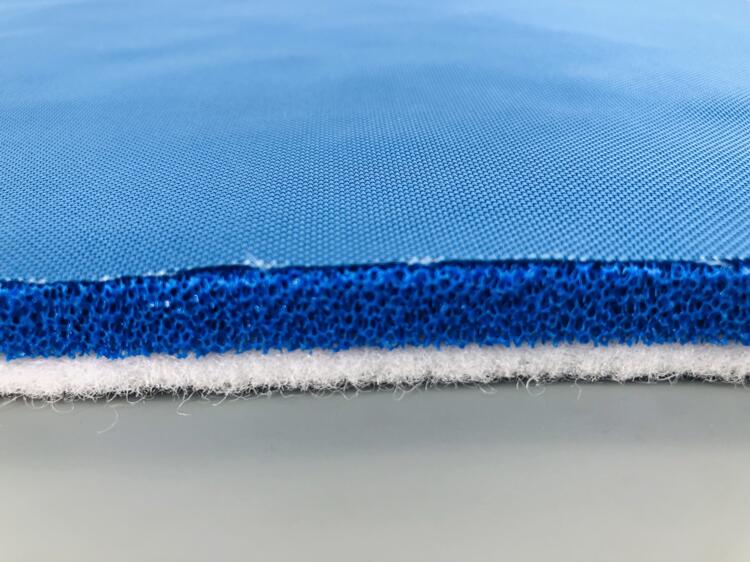

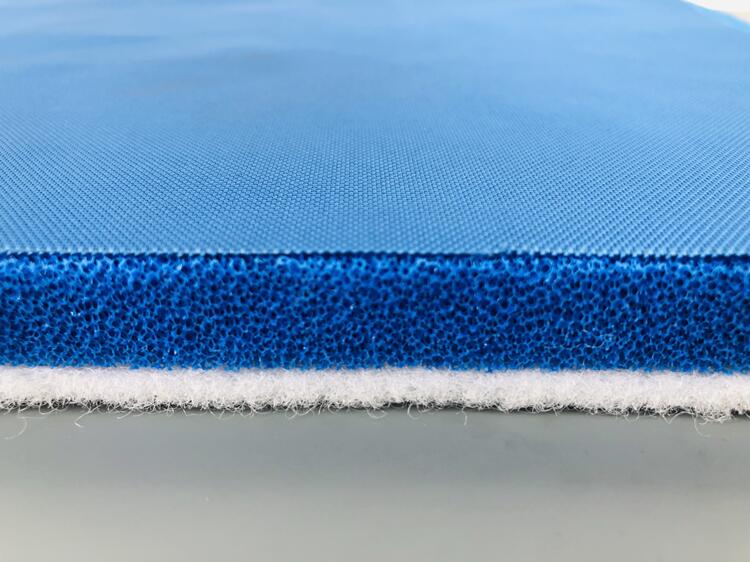

The intermediate padding (6-15 mm thick)

The padding used in ironing is an essential component in achieving a polished and wrinkle-free appearance. This layer of cushioning directly affects the softness of the fabric and ultimately impacts the overall ironing result.

Commonly a type of open cell silicone foam with at least 100 kgs weight per cubic meter is used as the intermediate padding. It must be porous to achieve the optimum permeability.

Applying a silicone coating can enhance the heat resistance of the foam padding.

Key Features:

1. Utilizing top-grade raw materials and employing cutting-edge production techniques

2. Exhibiting remarkable durability, elasticity, and heat resistance

3. Demonstrating excellent permeability for uniform steam diffusion

4. Ensuring the absence of hazardous chemicals during usage

5. Delivering consistently superior ironing results at a competitive price point

Regular products are: SBF-10, DH-10, DH-15, DH-20, DH-25, DH-30, DH-35, DH-40

Notes:

Relying solely on images makes it challenging to distinguish the density and quality of foam. The most effective approach to speed up the evaluation process is by exchanging samples with each other.

Final top cover

It is important that the final top cover used in ironing is not more heat resistant than the lower layers. This is because if the top layer is too resistant to heat, it may not be apparent when the lower layers have been exhausted, leading to a decrease in the quality of the ironing result.

Therefore, it is crucial to choose a top cover that is appropriately heat resistant to ensure optimal ironing performance.

In cases where the final top cover frequently becomes dirty and requires frequent replacement, it is recommended to opt for an affordable cover that can be easily replaced.

Regular products are: #11, #12 and #18

|  |  |

| #18 Blue polyester fabric cover | #11 Blue cloth for ironing tables | #12 Stretch polyester cover fabric |

9 Solutions Guiding You To Choose

In this section, I will provide you with a list of practical solutions that have proven to be popular among our customers. It is my hope that you will find inspiration and assistance from these suggestions.

S1: #18/SBF/P-600

| Structure | Materials | Thickness | Size |

| Top cover | #18 (Polyester fabric cover) | – | 1.5M * 100M |

| Intermediate padding | SBF (Expanded poly-foamed sheet) | 10mm, 7mm, 5mm | 1.3M * 10M |

| Lower padding | P-600 (White felt) | 6mm | 1.6M * 20M |

The above video shows this configuration.

#18 (No Stretch) is a light blue polyester cloth with a weight of 190 g/sqm and a height of 1500 mm. It is sold in linear meters and is commonly used for ironing boards that require a durable and substantial flow of fabric.

SBF refers to a polyurethane resin foam with a silicone-coated base, which is offered in three different thicknesses. The 5mm/7mm foam pad, known for its exceptional balance between price and performance, is commonly used as padding in simplest vacuum tables. On the other hand, the 10mm variant serves as the standard upholstery for vacuum tables.

P-600 is a type of needle felt made from polyester that is widely used due to its ability to withstand a range of temperatures and its affordable price point. It is a popular choice for many ironing tables and presses.

S2: #11/DH-10/P-300

| Structure | Materials | Thickness | Size |

| Top cover | #11 (Stretch polyester cover fabric) | – | 1.5M * 100M |

| Intermediate padding | DH-10 (Porous silicone foam) | 15mm, 10mm, 6mm | 1.5M * 10M |

| Lower padding | P-300 (White felt) | 3mm | 1.5M * 20M |

#11 (Stretch) with dark blue color as an elastic polyester fabric cover is designed to provide excellent ventilation. With a tightly woven construction, it offers durability and is resistant to damage during usage, resulting in a long lifespan. This cover is primarily used on ironing tables and pressing machines as a protective cloth.

DH-10 is ideal for vacuum tables and steam laundry presses equipped with a vacuum system. Its heat resistance, longevity, and labor-saving qualities make it a top choice for achieving a superior finish. Additionally, it is perfect for use on ironing tables. The foam is 60″ wide, features a soft blue color, and measures 6mm or 10mm in thickness per meter.

P-300 is a thin type of P-600. It is typically paired with DH-10 (10mm).

S3: #12/DH-15/P-802

| Structure | Materials | Thickness | Size |

| Top cover | #12 (Polyester fabric cover) | – | 1.5M * 100M |

| Intermediate padding | DH-15 (Silicon foam intermediate layer) | 15mm, 10mm, 6mm | 1.5M * 10M |

| Lower padding | P-802 (White felt) | 10mm | 1.5M * 20M |

#12 is the same stretch cloth as #11 but with green color. It offers good permeability, mechanical resilience, and a smooth surface that accelerates processing time.

DH-15 is a soft blue silicone foam, which is versatile and suitable for various applications. With its open-cell structure, it offers excellent heat and wear resistance. This foam is commonly used to create durable pads for vacuum ironing tables, ensuring longevity and reliability over time.

P-802 proves to be an exceptional felt choice for ironing on various types of ironing tables and presses. Its outstanding porosity ensures uniform steam distribution, while its heat and steam resistance contributes to its durability. We offer polyester needle felt in a range of qualities, weights, and thicknesses, providing flexibility to meet specific requirements.

S4: #18/DH-20/P-600

| Structure | Materials | Thickness | Size |

| Top cover | #18 (Polyester fabric cover) | – | 1.5M * 100M |

| Intermediate padding | DH-20 (Blue silicone foam padding) | 10mm, 6mm | 1.5M * 10M |

| Lower padding | P-600 (White felt) | 6mm | 1.5M * 20M |

DH-20 is highly elastic and super soft silicone foam, specifically engineered to effectively distribute air and steam. This foam is designed to be resistant to prolonged dampness, making it ideal for use as the outer softening layer in multi-layer covers for ironing tables. With the advancement of modern clothing finishing technologies, this type of foam is essential for achieving optimal results.

S5: #11/DH-25/P-300

| Structure | Materials | Thickness | Size |

| Top cover | #11 (Blue cloth) | – | 1.5M * 100M |

| Intermediate padding | DH-25 (Open cell silicone foam) | 10mm, 6mm | 1.5M * 10M |

| Lower padding | P-300 (White felt) | 3mm | 1.5M * 20M |

DH-25 boasts exceptional softness and excellent permeability for steam and air distribution. The inclusion of silicone rubber enhances its mechanical and thermal resistance, capable of withstanding temperatures up to 180°C. It can be utilized as part of two-layer covers, along with the upper BLUE COVER fabric for “cold” ironing tables, or as a softening foam for multi-layer covers on heated ironing tables and clothing presses. Its specific elasticity enables effective ironing without the risk of leaving any prints.

S6: #12/DH-30/P-802

| Structure | Materials | Thickness | Size |

| Top cover | #12 (Polyester fabric cover) | – | 1.5M * 100M |

| Intermediate padding | DH-30 (Silicone foam press pads) | 10mm, 6mm | 1.5M * 10M |

| Lower padding | P-802 (White felt) | 10mm | 1.5M * 20M |

DH-30 is particularly suitable for pressing large items like sheets and duvet covers, making it an ideal choice for steam ironing presses. With a thickness of 10mm, it allows the optimal amount of steam to penetrate the fabric during pressing while preventing excessive saturation of the pressing bed.

The expanded silicone possesses an extraordinary molecular memory, making it unparalleled for applications in hot presses, vacuum seals, and packaging. Its exceptional ability to regain its original shape sets it apart from other materials.

S7: #18/DH-35/P-600

| Structure | Materials | Thickness | Size |

| Top cover | #18 (Polyester fabric cover) | – | 1.5M * 100M |

| Intermediate padding | DH-35 (Silicone soft foam blue) | 10mm, 6mm | 1.5M * 10M |

| Lower padding | P-600 (White felt) | 6mm | 1.5M * 20M |

DH-35 is a unique polyurethane foam material with a medium density that is infused with a special silicone mixture. Thanks to its silicone content, this material is approximately three times the lifespan of latex foam. The superfine pores of this foam pad enable excellent vacuum properties and ensure optimal steam distribution. With its remarkably smooth surface, exceptional elasticity, and compatibility with delicate ironing fabrics, it is the ideal choice for demanding ironing applications.

S8: #18/DH-40/P-300

| Structure | Materials | Thickness | Size |

| Top cover | #18 (Polyester fabric cover) | – | 1.5M * 100M |

| Intermediate padding | DH-40 (Silicon foam intermediate padding) | 10mm, 6mm | 1.5M * 10M |

| Lower padding | P-300 (White felt) | 3mm | 1.5M * 20M |

DH-40 offers excellent porosity, ensuring even distribution of steam for consistent quality results. It maintains the elasticity and durability even with continuous use, making it resistant to heat and steam.

This foam pad is the ideal choice for achieving effortless and efficient ironing results on various pressing machines and ironing tables.

S9: #11/DH-20/VN/P-802

| Structure | Materials | Thickness | Size |

| Top cover | #11 (Polyester top cover) | – | 1.5M * 100M |

| Intermediate padding | DH-20 (Silicone press pads) | 10mm, 6mm | 1.5M * 10M |

| Buffering padding | VN (Perforated foamed silicone pads) | 10mm, 6mm, 4mm | 1.8M * 0.9M |

| Lower padding | P-802 (White felt) | 10mm | 1.5M * 20M |

VN is our 100% foamed silicone rubber, renowned for its consistent elasticity and standard softness. This material is perforated and napped to enhance the flow and dispersion of air and steam. With excellent mechanical and thermal resistance, it can withstand temperatures of up to 250°C.

Additionally, it is resistant to dampness and does not absorb water. This silicone ironing pad is perfect for use as the lower layer in multi-layer covers for clothing presses and ironing tables.

Notes:

If you want intermediate padding with temperature resistance over 180°C, here at Deer Hunter we have HS series silicone-impregnated PU foam special for sublimation, ironing and transfer printing applications.

Concerns Before Ordering

When you read here, I believe you have got some knowledge about how to cover your pressing machines and ironing tables.

To streamline your procurement process, you can also follow our Standard Operating Procedure (SOP) as below:

1: Please provide us with detailed information about your machine model, including any specific specifications or requirements.

2: Clearly state your specific needs, preferences, and any customization requirements for the desired solution. This will help us understand your expectations and tailor our solution accordingly.

3: Indicate your budget range or constraints. Knowing your budget will allow us to propose suitable options that align with your financial considerations.

4: As a professional and experienced company, we are committed to providing you with the best solution that meets your requirements and budget. Our team will carefully analyze your needs and develop a tailored proposal to address your unique situation. We strive to deliver high-quality results and exceed your expectations.

Conclusion

For some customized requirements, we will also provide targeted solutions.

|  |

Now, I want to hear from you.

Do you think today’s blog is helpful for your soucing coverings for ironing tables and presses?

Or Are you considering replacing your current foam pad with a new one from Deer Hunter?

Let me know by leaving a quick comment. Or contact our mobile/WhatsApp number +86-13823789007, or email us at sales@cndeerhunter.com