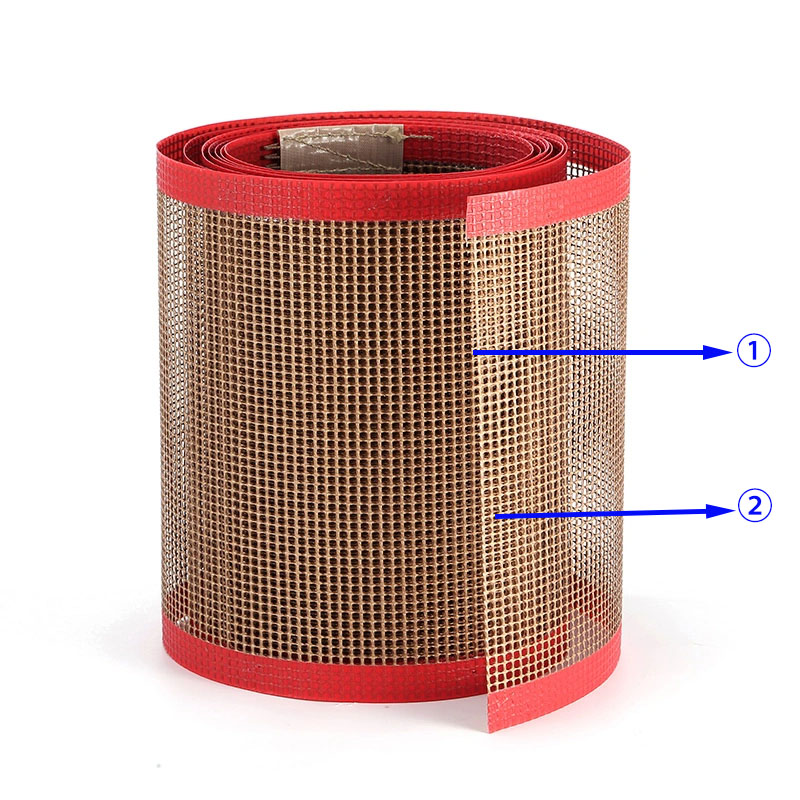

Open Mesh PTFE Coated Conveyor Belts

PTFE mesh conveyor belts are made from fiberglass or Kevlar mesh coated with PTFE, ideal for high-temperature settings that need good airflow through the belt. The PTFE coating also ensures excellent non-stick properties, making these belts a go-to for various product movement and drying applications. Our PTFE open mesh belts can be manufactured into endless conveyor belting with sealed edges as per your specifications.

What is PTFE Mesh

PTFE mesh is crafted from glassfiber or kevlar, coated with PTFE (polytetrafluoroethylene) resin. This base of woven fiberglass or Kevlar gives it excellent strength and stability. The PTFE coating makes the surface non-stick and able to handle temperatures ranging from -100°F to +550°F. The mesh design ensures high airflow and minimal heat loss, making it perfect for food-grade applications like dehydration sheets, grill mats, or conveyor belting for drying and curing processes. Typically, we offer different mesh holes, such as 1x1mm, 2×2.5mm, 4x4mm, 8x8mm, 10x10mm, with a max width of 4000mm. Custom lengths are available for special orders.

- ① Glass or Kevlar mesh fabric

- ② PTFE coating

Key Points Help You Order

PTFE mesh belts might seem common, but they’re not standard products. They involve details that need expert advice and tailored plans from suppliers. Here are essential factors to consider, drawn from our extensive experience, to guide you.

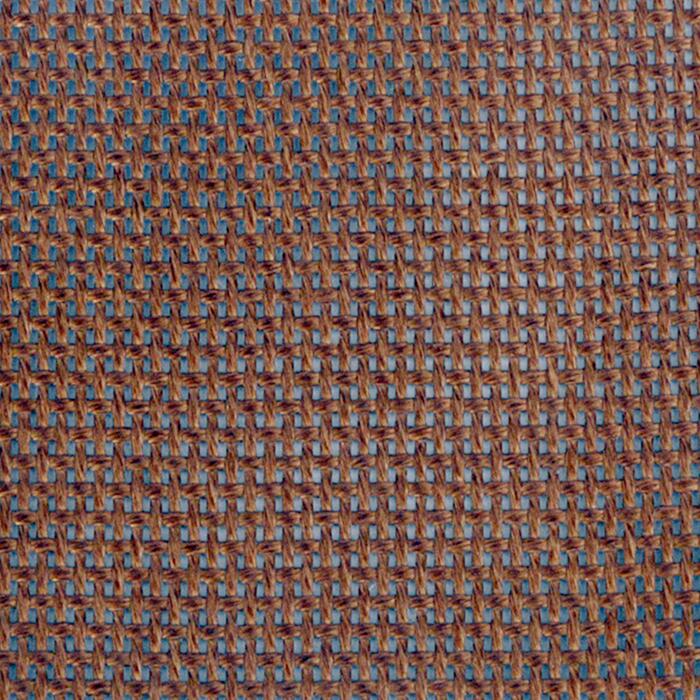

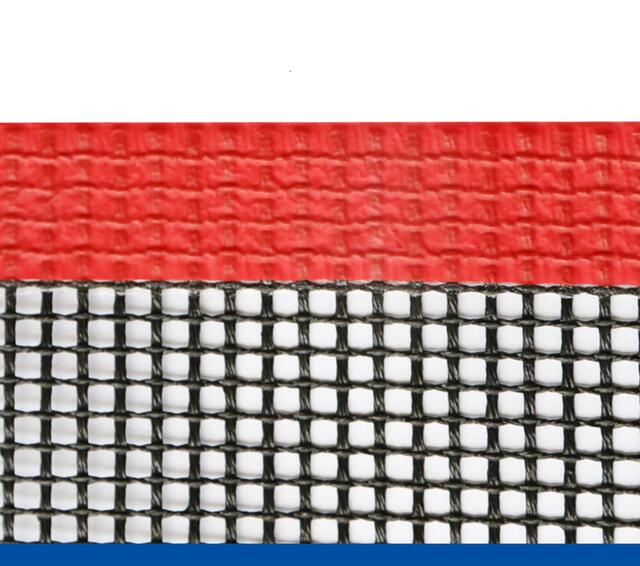

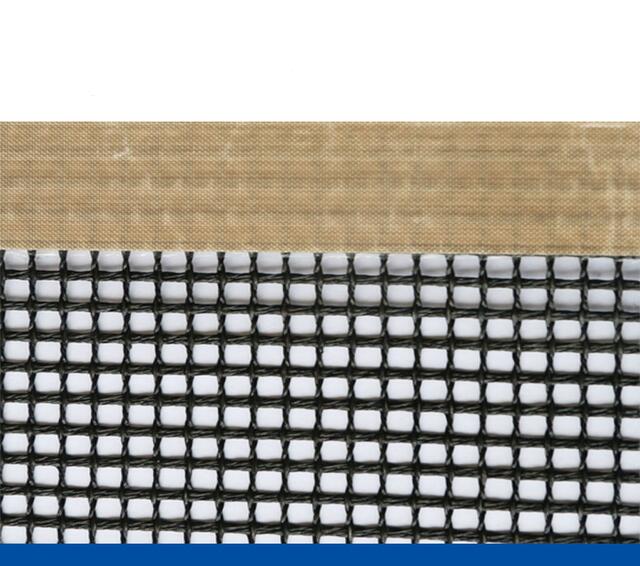

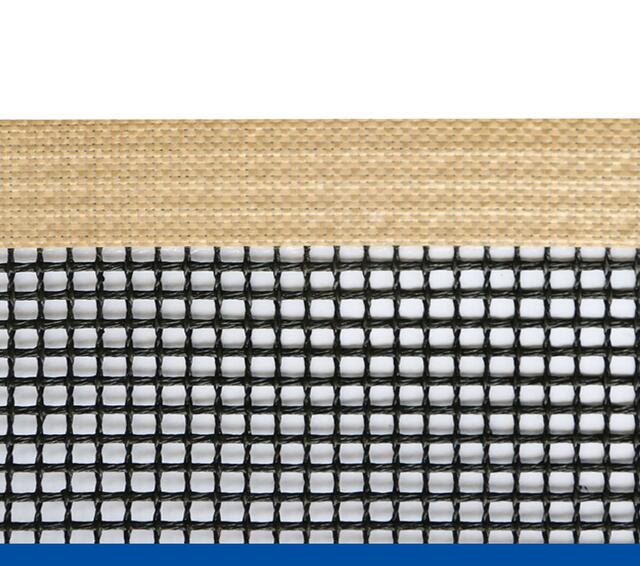

1: Colors

Brown color or Black color? Make your choice.

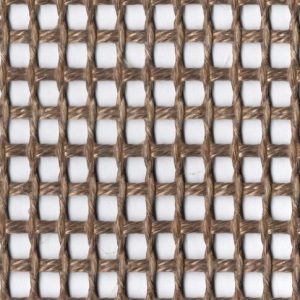

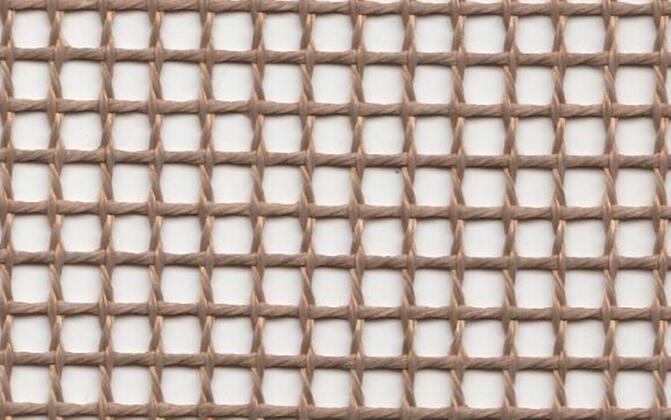

Brown Color

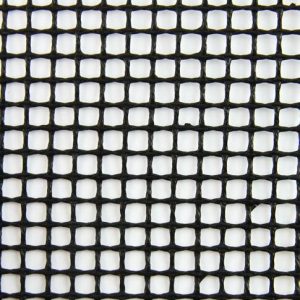

Black Color

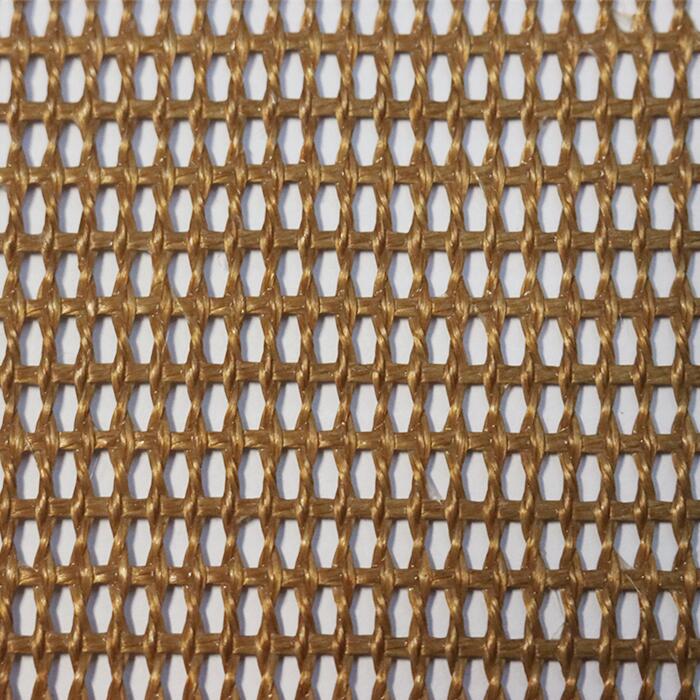

2: Double Weft (Stitching) Or Single?

The single weft mesh is perfect for food processing tasks like baking and dehydrating, ensuring safe and efficient cooking. For more demanding industrial tasks, our double weft mesh provides enhanced strength, making it ideal for laminating and material transport.

Double Weft

Single Weft

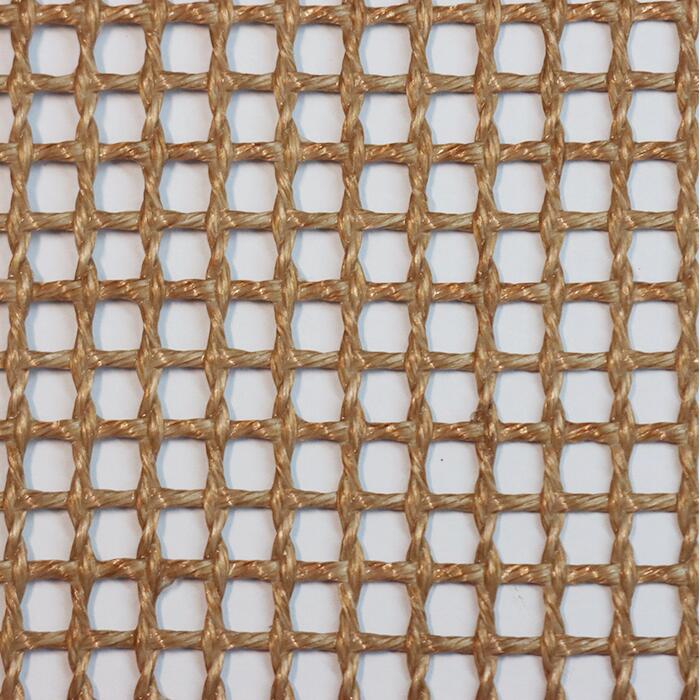

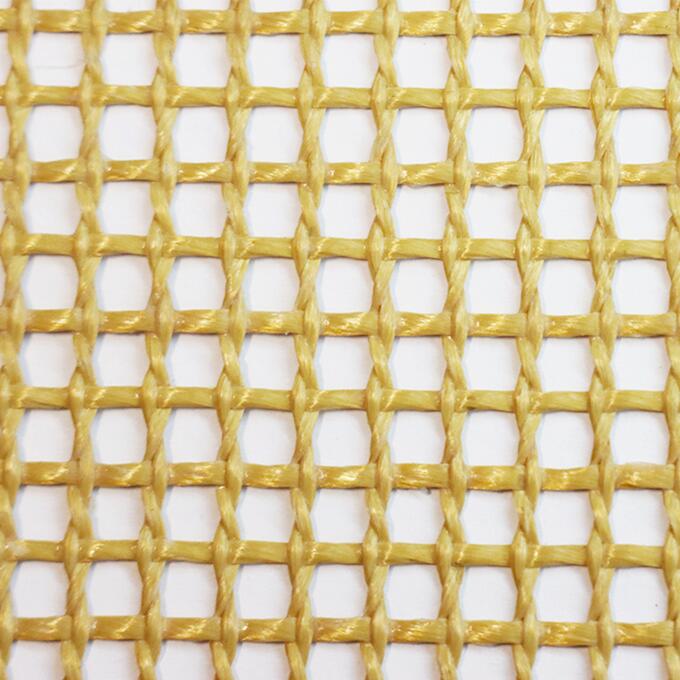

3: Mesh Openings

Let us know the application of your PTFE Open Mesh Belts and we can suggest which mesh openings, splicing and edging would be best suited. Additional information can be found as follows.

1mm X 1mm

Breathable but small article can’t drip from holes.

2mm X 2.5mm

Small holes and lower thickness, but with strong strength.

4mm X 4mm

Ideal holes for a wide range of common applications.

4mm X 4mm Kevlar

Aramid and combined glass/aramid are both available.

| Item No. | Mesh Size | Basic Material | Weight | Temperature | Max Width | Tensile Strength(Warp/Weft) |

|---|---|---|---|---|---|---|

| DH001 | 1 x 1mm | PTFE + glass | 470g/m2 | -70-260°C | 3000mm | 1600/1500N/5cm |

| DH001B | 1 x 1mm | PTFE + glass | 470g/m2 | -70-260°C | 3000mm | 1600/1500N/5cm |

| DH004 | 4 x 4mm | PTFE + glass | 480g/m2 | -70-260°C | 4000mm | 2100/1500N/5cm |

| DH004B | 4 x 4mm | PTFE + glass | 485g/m2 | -70-260°C | 4000mm | 2100/1500N/5cm |

| DH004D | 4 x 4mm | PTFE + glass | 580g/m2 | -70-260°C | 4000mm | 2800/1580N/5cm |

| DH004DB | 4 x 4mm | PTFE + glass | 580g/m2 | -70-260°C | 4000mm | 2800/1580N/5cm |

| DH004K | 4 x 4mm | PTFE + Kevlar | 465g/m2 | -70-260°C | 4000mm | 3500/3300N/5cm |

| DH10 | 10 x 10mm | PTFE + glass | 450g/m2 | -70-260°C | 3000mm | 1100/1100N/5cm |

| DH051 | 0.5 x 1mm | PTFE + glass | 470g/m2 | -70-260°C | 3000mm | 2200/1500N/5cm |

| DH225 | 2 x 2.5mm | PTFE + glass | 540g/m2 | -70-260°C | 3600mm | 2200/1500N/5cm |

The data herein are averages based on the authoritative testing of several lot numbers. This information is intended for comparison purposes only. Maximum continuous operating temperature is 500 °F/260 °C for all open mesh belts not including Kevlar® (356 °F/180 °C).

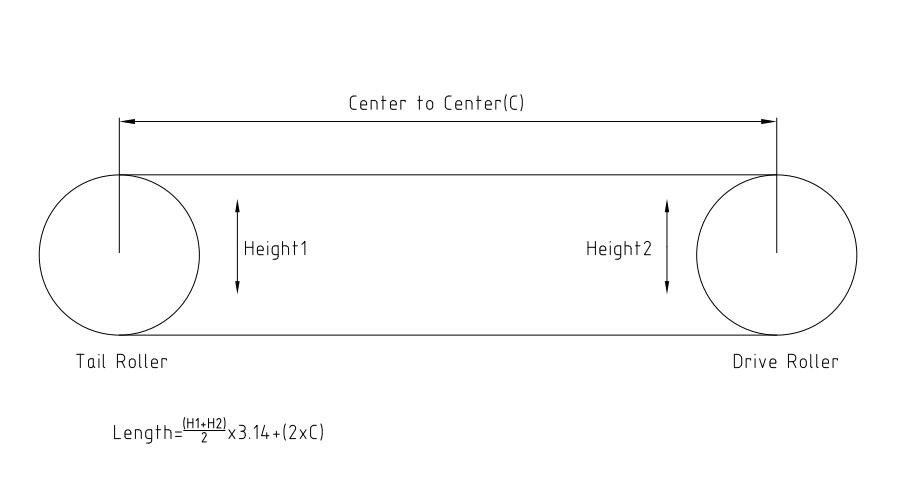

4: Width and Length

Non-standard belt sizes are available. Please contact your Sales Representative for more information.

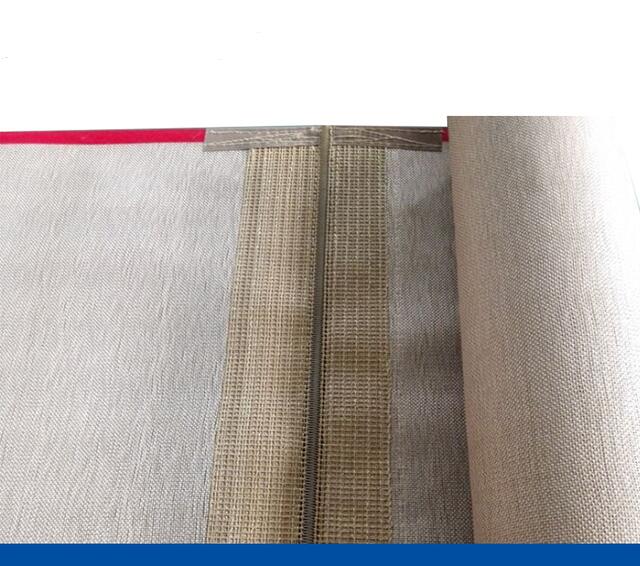

5: Protective Reinforcement Edges

To enhance the tracking and belt life, we use various PTFE films and PTFE-reinforced fiberglass fabrics to reinforce belt edges.

PTFE film (red) is the most common reinforcement material on the edges.

Heat Sealed PTFE Films

Integrated Seamlessly: Achieving a Flawless and Durable Finish

Heat Sealed PTFE Fabrics

Enduring Performance: Advanced Edge Protection

Kevlar Edge Reinforcements

Unmatched Strength for Extended Use: Reinforced with Kevlar Edging

For added durability, heat-sealed edges of open mesh belting can also be sewn upon request, providing an extra layer of reinforcement.

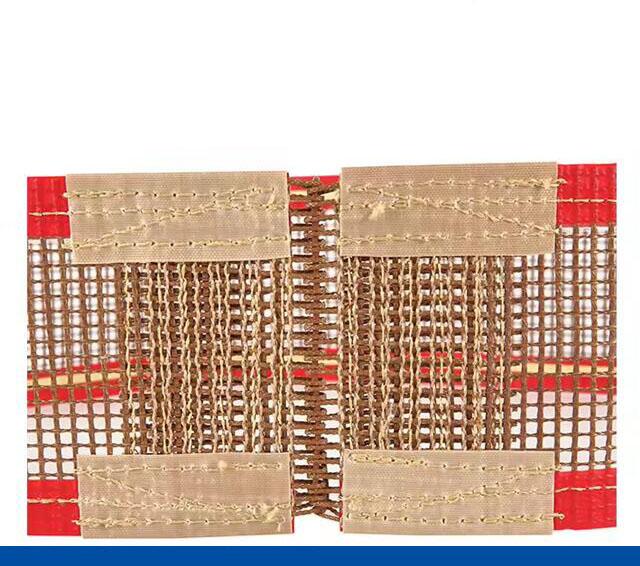

Sewn and Sealed

Edge reinforcement gets sewed and welded to accomplish optimal durability.

6: Belts Joints (Splice Options)

Proper belt running is only possible if we choose a suitable joint. We must take into account the following factors:

- Fabric type and thickness tailored to the specific use.

- Load capacity of the belt.

- Belt tension, roller diameter depending on the requirements of the surface structure.

Bullnose Joint

Most common. There are special eyelets at the end of the belt and the belt can be connected in place to an endless one with a plastic bar. Suitable for lighter joints, the spiral does not protrude above the surface of the tape and does not cause damage to the products.

Alligator Joint

Metal hooks are pressed into the ends of the belt, so that the belt can be joined into an endless one with a metal bar. It is possible to make sure that the hooks do not protrude above the surface of the belt. Suitable for belts with higher stress.

Castellated Joint

At both ends, loops of aramid or fiberglass foil are formed, which fit together and the belt can be joined in place with a plastic bar. Suitable for lighter joints, the spiral does not protrude above the surface of the belt and does not cause damage to the products.

Spiral joint

A special plastic spiral is attached to the ends of the belt and the belt can be joined in place to an endless one with a plastic bar. Suitable for lighter joints, the spiral does not protrude above the surface of the tape and does not cause damage to the products.

Frequently Asked Questions

How do I choose between PTFE Cloth, Kevlar Cloth, and PTFE Film for edge sealing?

Can these conveyor belts withstand high-temperature processes?

What benefits do Food Grade Teflon PTFE Mesh Conveyor Belts offer for my production line?

Are these conveyor belts safe for direct food contact?

How should I clean and maintain the conveyor belt?

How can we get in touch

We'd like to work with you!

Free samples are well prepared. We pay the freight. Our team will get back to you as soon as possible within 24 hours and help you select the right product you want.

- fullchance100

- 0086 13823789007

- export@cndeerhunter.com