If you are sourcing a silicone membrane for solar panel lamination, it can be challenging to decide which one to pick. There are many different types and brands of silicone membranes on the market, and each one has its own unique set of features.

In this blog post, I’m going to share the ultimate guide with you to understanding solar diaphragms and discuss the solar modules lamination process.

What Is Solar Panel Lamination?

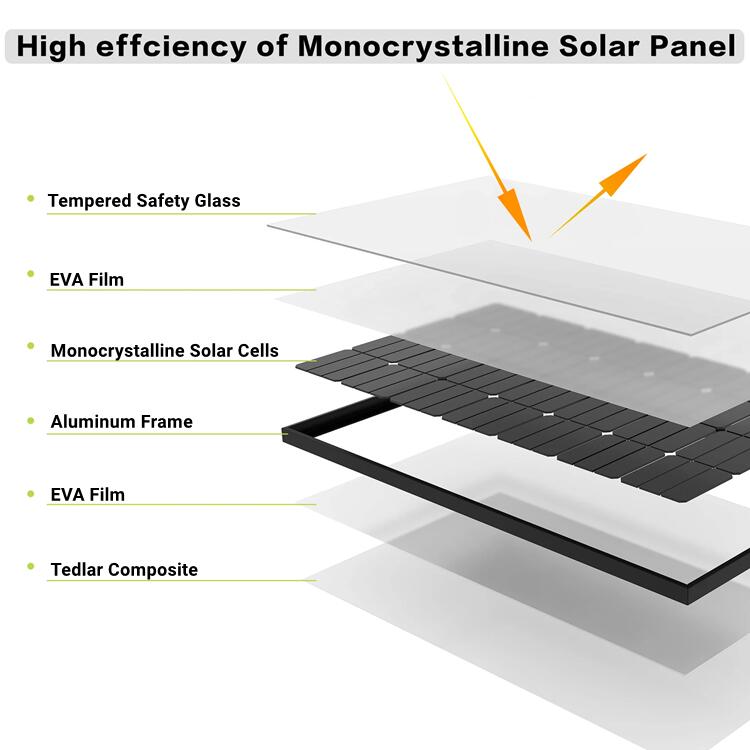

Solar panel lamination is the process of bonding together each of the vital elements that make up a solar panel, forming a high-performance photovoltaic system. This is commonly known as “lay-up” in the solar industry. The components used to make a solar panel are as follows in the order shown below.

- Tempered Clear Glass

- EVA (Ethylene Vinyl Acetate) Encapsulant

- Semi-Conductor / Power Cell

- EVA (Ethylene Vinyl Acetate) Encapsulant

- Bottom Cover (UV film) – Tedlar PVF Polyester Film

Photovoltaic panels are usually made of several layers including glass and aluminium that surround the actual solar cell. A layer of ethylene vinyl acetate (EVA) is used as an encapsulant to protect the highly sensitive solar cell. This is to sustain the cell’s power generating abilities through long term energy transfer, moisture accumulation and the impact of ultraviolet (UV) rays.

So, it prepares a 5-layer module. The operator puts this module in a solar panel laminator and pumps out the air from module layers. Then, it undergoes a heating process in the vacuum chamber to melt the encapsulant.

After that, the layers are pressed together with a flexible membrane. The operator heats it for roughly 20-22 minutes to a maximum temperature of 135°C.

It produces a sealed laminate with at least a 25-year lifespan for the solar cells. The operator removes excess EVA and TPT after the laminate has cooled and a junction box has fastened. To finish the procedure, you should frame the laminate.

Solar panels are exposed to a wide range of environmental elements and therefore require PV lamination which is crucial for the long-term integrity of solar cells. Without this encapsulation process, traditional PV modules would be subject to degradation due to weathering conditions – making it essential in order for them to remain effective over time.

Which Material Can Be Used In Solar Laminator?

During the PV module lamination process, module makers seal all components with ethylene vinyl acetate (EVA) adhesive film to ensure that module layers remain secure. High heat levels are needed to melt the EVA (typically 145-155 degrees C). These temperatures call for a flexible, durable membrane for use in the vacuum laminator to provide compression on the module in repeated cycles.

With advances in technology, silicone rubber sheets have emerged as a revolutionary product for the PV vacuum lamination process. Embodying superior tear resistance and flexibility through multiple cycles, these innovative materials help to reduce costs of service life while prolonging durability without sacrificing membrane performance.

Where To Buy China Solar Laminator Silicone Sheets?

1: Deer Hunter is a one-stop solution to get all types of silicone diaphragms. Here you can buy solar laminating silicone rubber sheets at moderate prices.

2: You can browse the sheets available on the website cndeerhunter.com. After that, you can select one that meets your needs and contact Deer Hunter’s customer executive.

3: Ask about pricing and the MOQ for the selected silicone rubber membrane. Look for suitable delivery options. If the terms and conditions satisfy you, you can place an order.

4: Make payment through a secure online payment gateway or bank transfer. The Deer Hunter team will arrange the specially developed rubber membrane for shipping to you.

Or you can enjoy following our standard purchase order process as below:

Types Of Silicone Rubber Membranes For Laminating Solar Panels?

Deer Hunter has launched three versions of silicone rubber sheets: The S2, The S5 and The S5+. Different to traditional diaphragm materials, the three types of products are specially designed to ensure the protection of PV modules and lamination equipment in extreme laminator temperatures and under challenging manufacturing environments.

The S5+ Gen version incorporates unique additives in its formulation to resist the EVA outgassing and can last more than 10,000 cycles, depending on EVA type, laminator model and process parameters. The S2 Gen version (grey silicone) provides an economic solution and is ideal for smaller module manufacturing plants.

To enhance the efficiency of the solar module manufacturing process and save costs for module makers, DH is launching its S5 Silicone Membrane for photovoltaic (PV) panel lamination.

Constructed from a modified silicone rubber material, The S5 Gen Silicone Rubber Sheet has very tight elongation features and demonstrates outstanding durability through repeated lamination cycles. Used as a processing aid in securing and sealing all module components with ethylene vinyl acetate (EVA) adhesive film, the membrane is highly resistant to EVA outgassing at the high heat exposure (up to temperatures of 220˚C) used in the module lamination process. It also retains its inherent flexibility and tear-resistance through repeated handling, protecting both the module and equipment to increase service life and lower costs.

Compatible Solar Laminator Brands With Our Silicone Diaphragms?

At this moment, the most common way to laminate solar PV panels is by using a solar module laminator. This old-fashioned method has many disadvantages but is used by the large majority of solar panel manufacturers.

When it comes to choosing a reliable supplier, trust is everything. Here you are in the right place to decide on the right silicone rubber sheet for the solar module laminator. Our silicone rubber sheets are specially designed to fit many brands of solar module laminators like Spire, Burkle, NPC, Meier, 2BG, Ecoprogetti, 3S, Komax, Electro Solar, Spaleck-Stevens, Nisshinbo, P-Energy, Mondragon, Boostsolar, Orient, ZST, etc.

Advantages Of Silicone Rubber Sheets For Solar Panel Laminator Machine?

There are many benefits of using silicone rubber membranes for solar panel lamination. Let’s discover some of them below.

1) Silicone membranes are inert materials.

Silicone membranes have good EVA resistant ability that does not break down or emit acetic acid. They are durable even at temperatures as high as 250°C or when exposed to UV rays.

It makes them a viable option for encapsulating solar PV panels. When the EVA polymer enclosure breaks down, it may be free. It decomposes in response to high temperatures or UV radiation.

2) Silicone rubber sheets offer more conversion efficiency.

A silicone rubber sheet is more transparent to solar radiation than EVA. Thus, you get 1.5% more conversion efficiency when you laminate PV panels with a silicone rubber membrane.

Thus, the silicone rubber sheet is becoming a more durable and flexible option for photovoltaic modules manufacture in the renewable energy market.

3) Rubber sheet for solar panels has an extended life span

The inertness of silicone rubber sheets extends the lifespan of PV panels significantly. They may endure much longer than 30 years. Additionally, they may convert 15% more energy than usual.

4) You can easily recycle silicone rubber sheet laminated solar panels.

Silicone sheet laminated panels are simple to recycle when a solar panel’s lifespan is up. However, it is not easy to recycle EVA laminated panels.

How To Prevent EVA Deterioration In Photovoltaic Membranes?

However, EVA has some side effects. Outgassing from the EVA as it becomes thermoplastic can degrade silicone diaphragms and cause them to become brittle, and then fail. Deer Hunter developed the S5 for the specific needs of the solar industry. The photovoltaic diaphragm is designed to resist the deterioration that results from EVA outgassing.

The S5 Gen laminator membrane is constructed of two layers of material. One layer is silicone backing material made from Hardness 55 shore A grey silicone. The second layer is resistant to the adverse effects of EVA which make standard silicone diaphragms deteriorate.

Another way to extend the life of the membrane is to protect it with a layer of high temperature PTFE fabric placed between the module and the sheet. PTFE is a water-resistant, anti-corrosive polymer and also highly heat resistant. Adding a sheet of PTFE within the module laminator can increase the life of the diaphragm as well as provide other production benefits.

PTFE sheets can be customized to the size and thickness specifications required for the photovoltaic industry. From many purchasing orders in the past, we can see thicknesses 0.25mm and 0.35mm are both preferred.

Tips For Using a Silicone Sheet For Solar Panel Lamination

Now, let’s talk about some valuable tips that can help you handle a silicone rubber membrane in a better way.

1) Handling

It is necessary to roll up the silicone rubber membrane and secure it with sturdy woven bags. Make sure you do this before transporting it.

A cardboard tube should be in the roll’s middle for further support. When received, this will make it simple to carry and unpack.

Stack extra rolls on pallets or in wooden containers. It will help to prevent damage during shipping if you want to transport sheets to another place.

2) Storage

Store the silicone diaphragm away from heat sources and direct sunlight. It will help if you store them at a temperature between -15 °C and +35 °C.

Additionally, it must not come into contact with salt, oil, and acid. It must also not come in contact with alkali or other corrosive materials. Finally, keep the roll at least one meter away from any heat source.

3) Use

The silicone rubber sheet mustn’t be under uneven pressure during use. It is also important to prevent iron filings and sand from entering the sheet. They can cause injury to workers.

Also, avert other impurities from entering the sheet.

4) Installation

It’s crucial to exert continuous, uniform pressure on the silicone sheet. It will help if you do this throughout the lamination process.

The sheet should not be too tight or loose at any particular place. For example, there should be no offset between the sheet’s round holes and the template holes.

Remember, the silicone sheet membrane may become tight due to thermal expansion and contraction, which is normal. It usually happens after the laminator is off and cools to ambient temperature.

5) Maintenance

The silicone membrane has a relatively soft texture. It doesn’t offer resistance to corrosive solid substances.

Thus, do not use strong solvents or acid-based solutions to clean its surface. Instead, clean the surface using neutral detergent or alcohol.

You should also carry out regular cleaning and treatment of the surface. It helps to avoid the buildup of EVA residue. Never use sharp objects on a silicone sheet, as this could result in very early damage.

FAQs About Solar Silicone Membranes

1) Will the sunlight damage my silicone membrane?

Silicone is often resistant to UV rays, making it less vulnerable to sunlight damage. Yet, some silicone types can deteriorate over time. They will be damaged if exposed to sunlight for an extended period.

It is more likely to happen with low-quality silicones. It is because they are silicones that are not for outdoor use.

On the other hand, high-grade silicones can endure prolonged exposure to sunlight. Thus, they will not significantly degrade.

2) What happens when the silicone sheet for solar lamination is overheated?

Due to its high melting point, silicone often does not burn or break down. It has to reach temperatures of over 600°F (315°C).

Yet, silicone can weaken and lose some of its physical characteristics. These characteristics include its tensile strength and elongation.

Furthermore, overheated silicone may generate smoke and chemicals that could be dangerous.

To ensure that silicone functions as intended, it is crucial to keep it from overheating. Also, it would be best to use it within the authorized temperature range.

3) How long does a wet silicone membrane take to dry?

The type and thickness of silicone, as well as ambient humidity, affect drying time.

Certain silicone types can fully dry in a few days. Yet, others may take many days to reach the touch-dry stage. In general, silicone rubber products will dry more slowly. They will dry slower than silicone sealants and adhesives.

It is a good idea to adhere to the manufacturer’s instructions. It will tell you about drying and curing durations.

Final Thoughts

Nowadays, people are getting more aware of solar panel lamination. They know how important it is to extend the lifespan of their panels.

The old-fashioned, traditional lamination processes used in the solar panel industry might save some money. But these old methods can damage solar panels.

There are also chances of cracking solar cells since it lacks a unique covering layer. So, it is best to avoid the old technique and embrace the new one.

Installing a silicone membrane during the lamination process of solar panels is necessary. It will help to ensure the durability and efficiency of the panels.

Moreover, it is crucial to follow proper installation techniques. You can achieve a robust and consistent bond and prevent damage to the silicone sheet.

Make sure you keep silicone rubber sheets away from corrosive substances and sharp objects. It is also essential to avoid contact with heat sources.

Are you looking for EVA resistant silicone rubber sheet for solar panel lamination?

Just send messages to me according to the right table sheet or directly contact me by emailing sales@cndeerhunter.com or via Mobile/Whatsapp/Wechat: +86-13823789007.