When it comes to looking for a top quality Teflon mesh to be used in a glass laminating machine, one must have a clear understanding of why this material is necessary and how it can improve productivity. Knowing the benefits of using Teflon mesh will allow you to make an informed decision and get the best product for your needs.

Glass laminating is the process of joining two or more layers of glass with an interlayer to create a single pane of glass that is stronger and safer. The interlayer material is typically made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) and is sandwiched between the layers of glass using a laminating furnace.

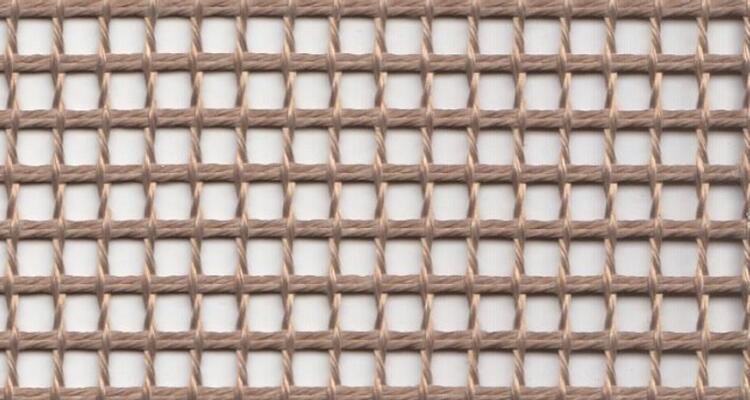

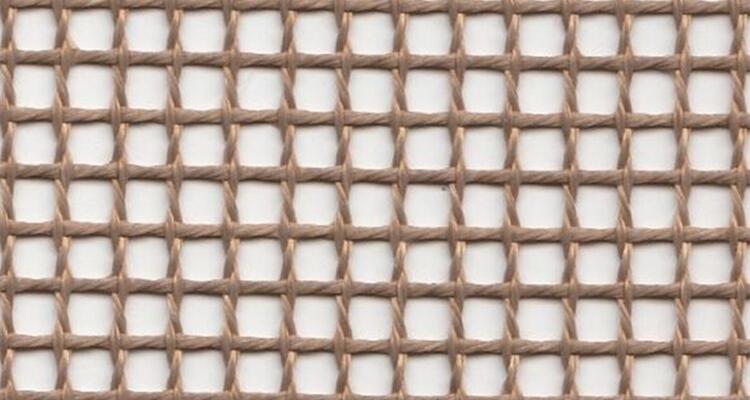

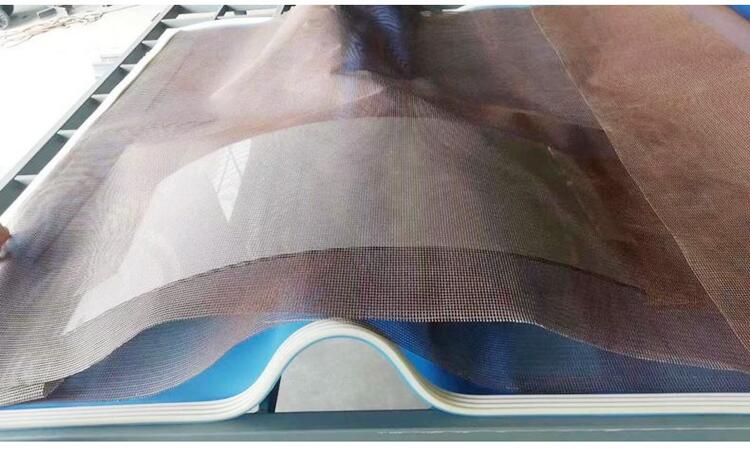

Teflon mesh is a permeable material used in glass laminating kilns to allow the proper heating and fusion of glass sheets and interlayers. Its thin, open structure facilitates even heat distribution, ensuring proper bonding of the materials.

In this article, I’m going to show you a comprehensive guide on Teflon mesh sheets for glass laminating machines.

What is Teflon Mesh?

Teflon mesh is made up of fibreglass fibers that have been coated with a layer of PTFE (polytetrafluoroethylene) resin. This combination of materials makes it extremely heat resistant, making it ideal for use in the creation of laminated glass. It ensures that all components involved in the lamination process are fused together properly, providing a strong and durable finished product.

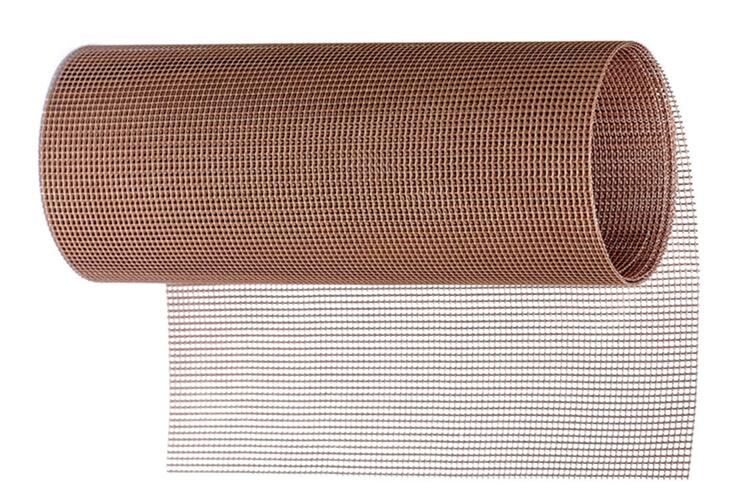

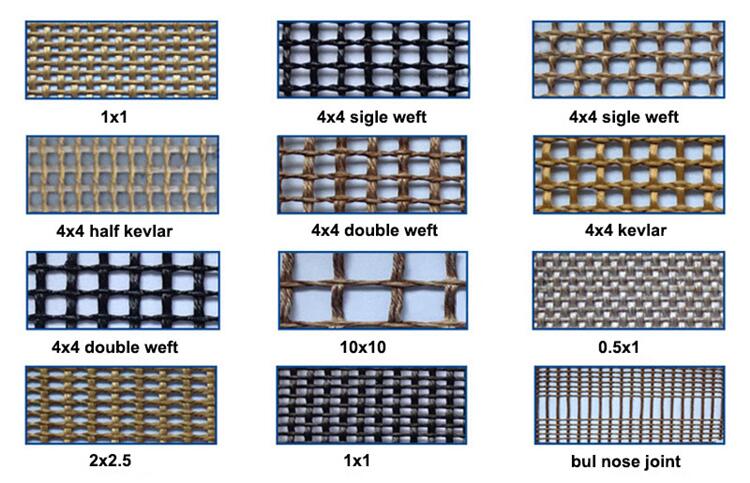

Teflon mesh screen comes in various sizes and can be custom-cut to fit the specific requirements of a laminating machine. It defines the specifications in terms of mesh size, mainly including 1mm*1mm, 2mm*2mm, 4mm*4mm, 10mm*10mm, etc., and is divided into single weft and double warp and weft grids according to the different warp and weft band.

Which Model is Widely Used in a Silicone Vacuum Bag?

Normally, our DH004D with 4mm*4mm mesh hole is used in this application, and any size can be customized according to different machines.

Product Specifications:

| Item | Teflon Mesh |

| Model No. | DH004D |

| Color | Brown |

| Max Width | 4000mm |

| Thickness | 1mm |

| Weft | Double |

| Mesh Size | 4mm*4mm |

| Weight | 580g/m2 (17.1 oz/sq yd) |

| Tensile Strength (warp) | 560 N/cm (331 lbs/inches) |

| Tensile Strength (weft) | 316 N/cm (181 lbs/inches) |

| Temperature range | -73-315℃ (-100-600℉) |

Deer Hunter offers more durable Teflon mesh sheet in stronger weft and warp which will extend its life a lot.

|  |

| Stronger 4mm*4mm Double Weft | Normal 4mm*4mm Single Weft |

Benefits of Using Teflon Net

There are several benefits of using Teflon open mesh in a glass laminating machine, including:

Non-Stick Surface:

Teflon mesh’s non-stick surface is perhaps its most significant feature. This prevents the glass and interlayer material from sticking to the mesh during the laminating process, which can cause damage to the materials and reduce the quality of the laminated glass. The non-stick surface also makes it easy to clean the mesh, which is crucial in maintaining the machine’s efficiency.

High-Temperature Resistance:

Teflon mesh is highly resistant to high temperatures, making it ideal for use in glass laminating machines. It can withstand temperatures of up to 260°C without melting or degrading, which is essential for the laminating process.

Chemical Resistance:

Teflon mesh is resistant to most chemicals, which makes it suitable for use with various types of interlayer materials. This ensures that the mesh does not degrade or become damaged when exposed to chemicals during the laminating process.

Durability:

Teflon mesh is a durable material that can withstand wear and tear over an extended period. It is also resistant to abrasion, which ensures that it maintains its non-stick properties even after multiple uses.

Customizable:

Teflon mesh can be custom-cut to fit the specific requirements of a laminating machine. This ensures that the mesh fits snugly and correctly within the machine, which is crucial for the laminating process’s efficiency.

Improved quality of laminated glass:

Due to its safety and noise control properties, laminated glass find wide applications in the construction industry, architecture and interior design. Laminated glass is made of two or more layers of glass sandwiched with PVB or EVA diaphragm between them and treated by high temperature and high pressure in a silicone vacuum bag.

Teflon mesh is used in the vacuum process, for it withstands high temperature, provides good release surface and excellent porosity under pressure. This results in laminated glass that is of high quality and meets industry standards.

In summary, using Teflon mesh in a glass laminating machine improves the efficiency of the laminating process, enhances the quality of the laminated glass, and ensures that the machine lasts for a long time.

How to Install Teflon Mesh Sheets?

The installation of Teflon mesh on a glass laminating machine is a straightforward process. Follow these steps to install Teflon mesh on your machine:

Remove the old Teflon mesh:

If your laminating machine already has a Teflon mesh, remove it before installing the new one. Carefully remove the old mesh from the machine.

Clean the machine:

Before installing the new Teflon mesh, clean the laminating machine and silicone bag thoroughly. Remove any debris or dust that may have accumulated inside the machine.

Cut the Teflon mesh:

Measure the size of the real working area where the Teflon mesh will be installed and cut the mesh accordingly. Ensure that the mesh fits snugly and correctly within the machine.

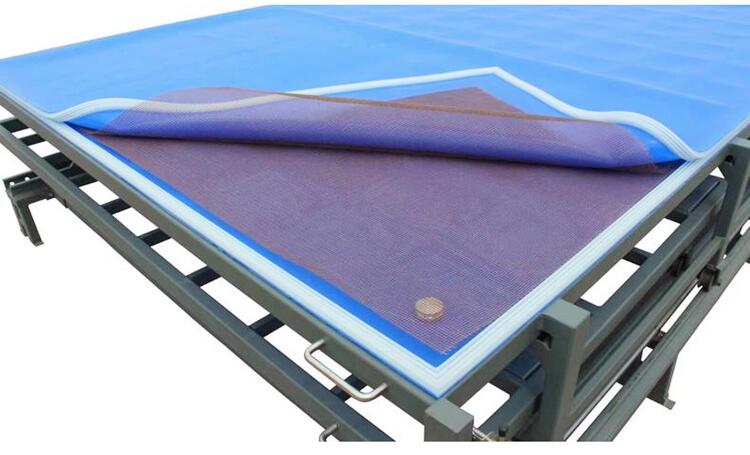

Install the Teflon mesh:

Place the Teflon mesh on the machine, making sure that it covers the entire area where the glass and interlayer material will be placed.

How to Properly Prepare and Manage Teflon Mesh?

Proper preparation and management of Teflon mesh in a glass laminating machine are essential for ensuring that the machine operates efficiently and produces high-quality laminated glass.

Here are some tips on how to prepare and manage Teflon mesh:

Cleaning:

Before using Teflon mesh, it is important to clean it thoroughly to remove any dirt, dust, or debris that may have accumulated on the surface. Use a soft cloth or sponge and a mild cleaning solution to wipe down the mesh, being careful not to scratch or damage the Teflon coating. Rinse the mesh with clean water and allow it to dry completely before using it.

Cutting:

Teflon mesh should be cut to fit the specific requirements of the laminating machine. Use a sharp pair of scissors or a cutting tool to cut the mesh to the correct size and shape. Be careful not to cut or damage the Teflon coating, as this can affect the mesh’s non-stick properties.

Storage:

When not in use, Teflon mesh should be stored in a dry and clean environment. It is recommended to store the mesh flat or rolled up, as folding or creasing the mesh can cause damage to the Teflon coating. Avoid storing the mesh in direct sunlight or near sources of heat, as this can cause the mesh to warp or degrade.

Replacement:

Teflon mesh should be replaced periodically to ensure that it is functioning correctly. Signs that the mesh needs to be replaced include visible damage to the Teflon coating, warping or distortion of the mesh, or a loss of non-stick properties. Regular replacement of Teflon mesh can help to ensure that the laminating machine continues to operate efficiently and produce high-quality laminated glass.

Maintenance:

Regular maintenance of the laminating machine is essential for ensuring that the Teflon mesh operates correctly. This includes cleaning the machine regularly, checking for wear and tear on the mesh and other components, and ensuring that the machine is properly calibrated.

By following these tips, you can ensure that the Teflon mesh in your glass laminating machine is properly prepared and managed, which will help to ensure that the machine operates efficiently and produces high-quality laminated glass.

Where to Buy Teflon Mesh for Laminated Glass?

Teflon mesh sheets can be purchased from various manufacturers, suppliers, and distributors. Here are some options to consider:

Online retailers:

There are several online retailers that sell Teflon mesh for glass laminating machines, such as Amazon, eBay, and Alibaba. These retailers offer a wide range of options at competitive prices.

Glass laminating machine manufacturers:

Manufacturers of glass laminating machines often sell Teflon mesh as part of their product offerings. Contact the manufacturer of your laminating machine to inquire about purchasing replacement Teflon mesh.

Speciality suppliers:

There are speciality suppliers that offer Teflon mesh specifically for glass laminating machines. These suppliers often provide custom-cut mesh to fit the specific requirements of your machine. At Deer Hunter, we offer the best Teflon mesh for your laminate glass processing.

When purchasing Teflon mesh for your glass laminating machine, it is important to ensure that the mesh is the correct size and thickness for your machine. It is also important to choose a reputable supplier that provides high-quality products and excellent customer service.

Other Uses Besides Teflon Mesh for Glass Processing

Teflon mesh has a variety of applications beyond its use in glass laminating machines. Here are some other common applications of Teflon mesh:

Food processing:

Teflon mesh is commonly used in the food industry as a non-stick surface for cooking and baking. It can be used to line baking sheets, grills, and oven racks, or as a conveyor belt for food processing equipment.

Screen printing:

Teflon mesh is used in screen printing to support the stencil and ensure that the ink is applied evenly to the substrate. It is also used as a non-stick surface for drying printed materials.

Drying applications:

Teflon mesh is commonly used in drying applications, such as in the textile industry, where it is used to dry fabric without leaving any marks or impressions.

Chemical processing:

Teflon mesh is resistant to many chemicals and is therefore used in chemical processing applications, such as in the production of acids, fertilizers, and other chemicals.

Aerospace and aviation: Teflon mesh is used in the aerospace and aviation industries as a non-stick surface for parts and equipment that are subject to high temperatures or extreme conditions.

Medical applications:

Teflon mesh is used in medical applications, such as in the production of surgical implants and as a non-stick surface for medical equipment.

Automotive industry:

Teflon mesh is used in the automotive industry as a non-stick surface for paint and adhesive applications, as well as for filtration and sealing applications.

These are just a few examples of the many applications of Teflon mesh. The versatility and non-stick properties of Teflon make it a popular material for a wide range of industrial and commercial applications.

Top 5 FAQs

1. Can Teflon mesh be folded into blocks during transport?

Transporting Teflon mesh in foldable blocks is not recommended, as the internal properties and longevity of the material may be compromised. This means customers must factor in extra costs for freight forwarders who charge overlength fees.

2. How long does Teflon mesh last?

The lifespan of Teflon mesh depends on several factors, such as the frequency of use, the temperature and pressure settings of the laminating machine, and the type of glass being laminated. With proper care and maintenance, Teflon mesh can last for several years.

3. Can Teflon mesh be reused?

Yes, Teflon mesh can be reused multiple times if it is cleaned and maintained properly. Be sure to inspect the mesh for any signs of wear or damage before using it again.

4. How do I know if I need to replace my Teflon mesh?

If the Teflon coating is worn or damaged, or if the mesh is torn or frayed, it may need to be replaced. Additionally, if the mesh is not providing an adequate release, it may be time to replace it.

5. How to order Teflon mesh?

That’s very easy. Just send us an inquiry and let us know the size (width * length) and quantity you need.

Conclusion

Teflon mesh has a special purpose in the production of laminated glass. It is laid above and below the glass, which mainly plays the role of air diversion to prevent the phenomenon of “false vacuum”. In addition, it can also prevent the vacuum bag from being scratched by the glass.

Now, it’s your turn. I want to hear from you.

What do you think of this guide about Teflon mesh?

Or maybe I missed something useful you want to know.

Either way, If you still have any questions about it, you can send messages through the right table sheet. Or you can contact us directly via mobile/whatsapp +86-13823789007 or email to sales@cndeerhunter.com